Printed Models with ProJet and Envision TECStereo Lithography Apparatus (SLA) 3D printing uses a UV-sensitive liquid resin as the working material. A UV-laser is projected on and moves across the reservoir of the resin build material, illuminating and hardening the liquid resin only in the areas where the part is being printed. If multiple parts are being printed, each part is traced on the resin by the laser. The platform holding the part or parts lowers after each layer is printed, and a wiper blade spreads more build material uniformly across the working space. The UV laser makes another pass, tracing the outline of the next layer for each part in the print job. The process is repeated layer by layer until the job is complete. SLA technology allows for varying the layer thickness throughout the printing process. Some layers can be 100 µm thick where accuracy is not critical and then dialed to 50 µm or less when greater accuracy is required. SLA printing technology is available with a wide variety of materials. A 25-µm to 50-µm layer thickness is achievable with excellent accuracy and good surface finish. SLA typically has slower build times due to the laser outline of each part. Post-print processing may require cutting the final part from the support material, removal of excess material, and the parts placed in a UV oven for final curing. Additive manufacturing technology in the dental industry is gaining popularity.. Materials and printing techniques continue to improve as manufacturers receive feedback on what is needed in terms of performance. The volume of single-unit production in the dental industry is unlike anything the RP industry has encountered before. Dentistry is quite possibly the ultimate industry for RP technology to move into. Additive manufacturing equipment makers and material suppliers for these printers are already taking notice.

The ProJet SD 3000 prints high definition, durable plastic parts for engineering and mechanical design applications including functional testing, form and fit verification, rapid prototyping, design communication, rapid tooling and more. Superior VisiJet materials deliver exceptional quality and the unique part support is the easiest and fastest to remove, even from complex, inaccessible internal geometries. Visit sldtech.com for more information

CAD/ CAM systems and 3D printing are changing the dental industry at a very fast rate. The success of the digital dental lab implementation relies heavily on:

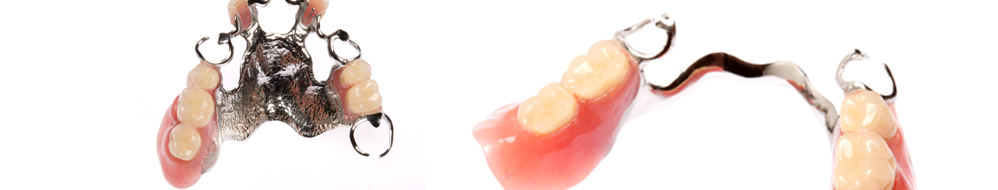

CAD-based dental restorations using Envision TEC 3D printers deliver labor and material cost reduction as well as higher clinical quality and consistency throughout the manufacturing process. Labs need to compete with offshore production. Our low-cost, high-throughput solutions offer the requisite quality to level the global playing field and improve dental lab competitiveness. EnvisionTEC 3D printing solutions are optimized for a number of materials representing a broad portfolio of dental and orthodontic applications. Whether you use 3Shape, Dental Wings, or any other design software product, a finished product is only a few clicks away. As software and material upgrades become available, this information is provided to EnvisionTEC customers. We are in constant communication with the R&D teams of the most recognized dental CAD software companies to ensure a seamless workflow that delivers consistent manufacturing quality. 360SDM Dental Milling Center is a dental milling center for dental laboratories (USA), offering unrivaled milling quality for its customers at a fair price-performance ratio: zircon milling center, CAD/CAM dental milling, milling center e.max®, dental scanner, CAD/CAM abutment tooth colored PMMA, IPS e.max® CAD, 7Series scanner, 3Series scanner, dental CAD software, Dental Wings Scanner, Dental Wings Software, DWOS. |

|

You are here: 360SDM > Dental Milling Center > Model Printing